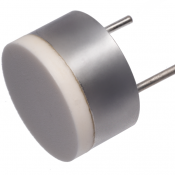

Ultrasonic Transducer (Electrostatic & Piezoelectric)

-

PID 604142 – Series 600 Instrument Grade Ultrasonic Transducer

$29.65 / per piece -

PID 607281 – Series 600 Environmental Grade Ultrasonic Transducer

$28.57 / per piece -

PID 607285 – Series 600 Environmental Ultrasonic Transducer with Parylene

$36.65 / per piece -

PID 604144 – Series 600 Open Face Ultrasonic Transducer with Parylene

$36.65 / per piece -

604150 – Series 600 Open Face Ultrasonic Transducer without Parylene

$36.65 / per piece -

PID 612366 – Series 7000 Ultrasonic Transducer with Clips

$24.25 / per piece -

PID 614565 – Series 7000 Ultrasonic Transducer without Clips

$24.25 / per piece -

PID 618417LF – Series 9000 Transducer, RoHS

$26.17 / per piece -

PID 618909LF – K Series 125KHF25, RoHS

$73.38 / per piece -

PID 618907LF – K Series 200KHF18, RoHS

$80.68 / per piece -

PID 625598LF – K Series 40KT18, RoHS

$15.30 / per piece -

PID 625599LF – K Series 40KR18, RoHS

$15.30 / per piece

Frequently Asked Questions about Ultrasonic Transducers

Why consider Senscomp for manufacturing ultrasonic transducers?

SensComp, a world leader in ultrasonic sensors, offers a large selection of in-air ultrasonic sensors, ranging components, complete plug-and-play systems and educational and evaluation kits. Our kits provide a low-cost method of learning about and evaluating various ultrasonic sensors and components to assist you in product development and prototyping.

SensComp understands the costs and frustrations inherent with technology and its development. Our goal is to provide our customers with leading edge ultrasonic sensors and components that are high quality, low cost, and easy to use.

What are the types of ultrasonic transducers?

There are two types of ultrasonic transducers: Electrostatic and Piezoelectric.

What are the key differences between Electrostatic & Piezoelectric transducers?

Electrostatic transducers are made up of a fixed electrode and a movable electrode, charged electrostatically in opposite polarity; motion of the movable electrode changes the capacitance between the electrodes and thereby makes the applied voltage change in proportion to the amplitude of the electrode’s motion.

Piezoelectric transducers are a device that uses the piezoelectric effect to measure changes in acceleration, pressure, strain, temperature or force by converting this energy into an electrical charge. When we squeeze this piezoelectric material or apply any force or pressure, the transducer converts this energy into voltage. This voltage is a function of the force or pressure applied to it.

Electrostatic devices have a higher sensitivity and bandwidth than piezoelectric devices. Electrostatic devices have a relatively flat response over a wide frequency range, and because they are non-resonant, have very low ring-out characteristics. Such devices are more sensitive than their piezo counterparts, typically by 40 dB or better.

The increased sensitivity translates into longer-range capabilities (or lower-gain receive circuits for shorter-range applications) and the ability to sense small and acoustically absorptive targets more reliably than piezo transducers. A single electrostatic transducer coupled with the proper electronic driver and receiver can cover a range of 1 inch to over 40 feet, making them a good choice for deep tank level measurement applications. Electrostatics outperform piezoelectrics in all functional areas except for size and ruggedness.